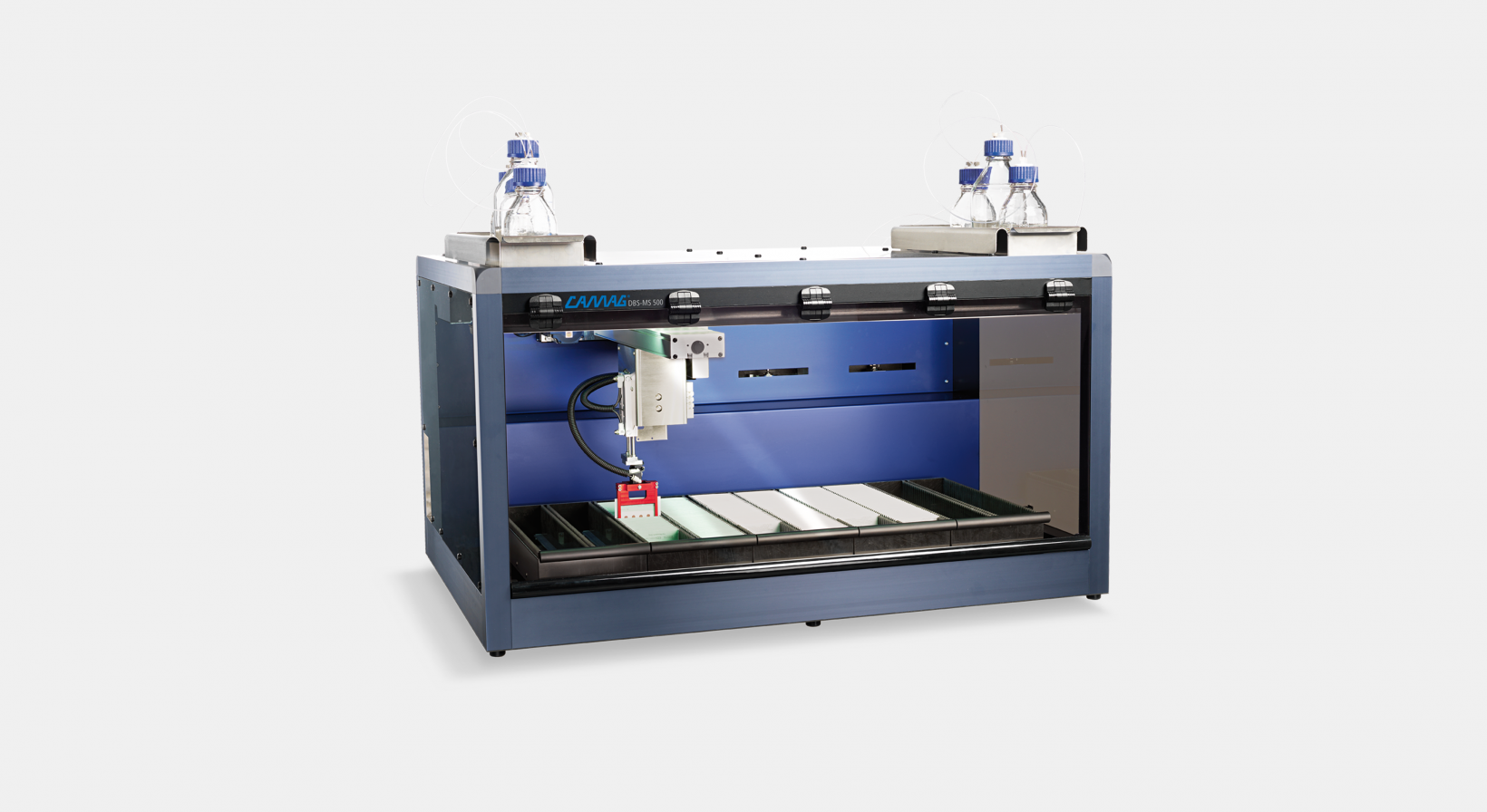

The fully automated DBS-MS 500 HCT from CAMAG contains state-of-the-art technology to extract target substances out of a DBS (Dried Blood Spot). The DBS is directly eluted in the extraction chamber and the analytes are guided online to the analytical system of choice or the extract is collected into a vial or 96 well plate. Sample processing is automated, including the application of an internal standard through a high-precision sprayer, detecting the sample's hematocrit through an optical module, and a barcode assignment from the DBS card. In addition to the analytical results, a picture of each DBS card before and after extraction and the run parameters are reported to maintain full traceability and the highest quality.

Key Features

- High-throughput analysis of up to 500 DBS cards per run

- Integrated optical card recognition and barcode reading module

- Non-destructive hematocrit detection through an optical module

- Automated internal standard application module

- Unique extraction module with wash station to eliminate carry-over

- Online coupling to the analytical system (MS or LC-MS)

- Full control through Chronos software

The fully automated CAMAG DBS-MS extraction system makes DBS analysis remarkably easy and has strong advantages compared to both, the manual and semi-automated punching techniques. With the CAMAG DBS-MS 500 HCT extraction procedure, DBS analysis is an economical alternative to conventional blood sampling. It represents a time- and cost-saving technique to analyze pharmacological samples, and is less invasive for participants or animals.

Workflow

The CAMAG DBS-MS 500 HCT offers a solution for the complete laboratory analysis workflow. Through the integration of the internal standard via an automated sprayer prior to the extraction, potential extraction differences are compensated.

1. Robotics

Highly reliable robotics handle the DBS cards from 5 separate racks, each with a capacity of 100 cards. The gripper picks up cards and moves them to all of the subsequent processes in the corresponding modules and back into their original position after the extraction. All DBS cards in the standard format of 84.5 mm x 53 mm can be used, independent of the brand.

2. Optical card recognition

The spot number and position, checkbox status, and barcode information are determined by a camera module. The connection between the DBS and its barcode is ensured throughout the whole process. CAMAG has incorporated its know-how of more than a decade of optical HPTLC image analysis to build this precise and reliable camera module.

3. Hematocrit detection module

An optical hematocrit detection module scans the DBS' surface at a specific wavelength, where the spectra of hemoglobin and the oxidation products overlap. By measuring the reflectance of the DBS, we get a signal proportional to the sample's hematocrit independent of age (patented). An algorithm calculates and displays the sample hematocrit directly in the software. The detection is also independent of humidity, the presence of other proteins or external blood factors (list of drugs tested by CAMAG DBS laboratory).

4. Internal standard application

The extraction efficiency and quality are ensured via the application of an internal standard prior to the extraction. The internal standard solution is applied with a high-precision sprayer onto the DBS. CAMAG has been manufacturing high-precision application instruments for HPTLC for many years and has implemented this knowledge to build a highly reliable spraying module.

5. Extraction module

The extraction unit seals the DBS card and the extraction solvent is pressed horizontally through the DBS into a sample loop or trapping column. The extraction volume and the extraction solvent composition can be chosen depending on the application. The extract is guided online to the analytical system and is independent of the extraction solvent cycle.

6. Wash station

A designated wash station cleans all parts that are in contact with the DBS cards and additionally flushes the entire tubing to avoid any carry-over between samples. Carry-over is therefore not an issue, as independent user tests have confirmed.

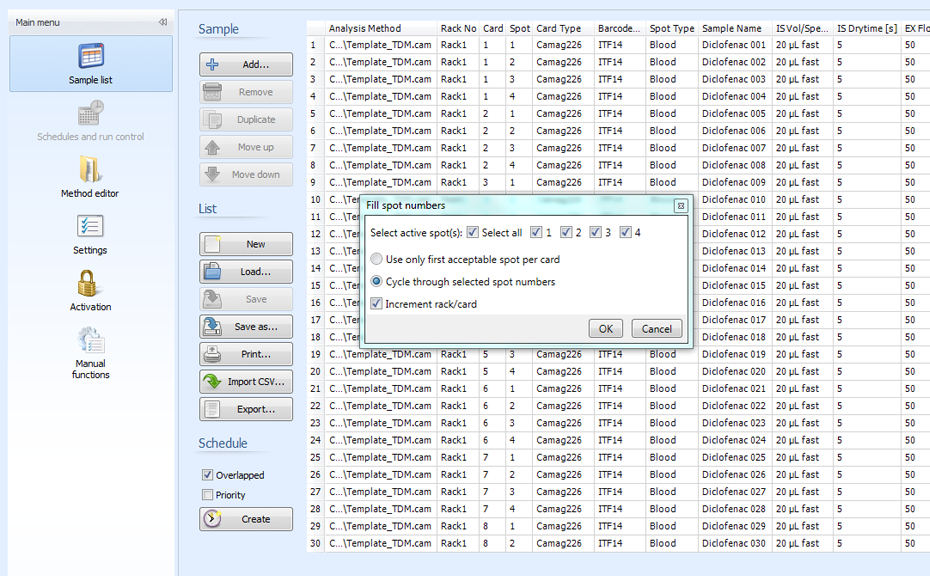

7. Master control software Chronos

Chronos is a sophisticated master control software that manages your analytical system in addition to controlling the DBS-MS 500 HCT. Sample lists are programmed in Chronos, bringing sample processing, extraction, and analysis parameters together. Chronos is compatible with the majority of common MS software and allows data exchange between those programs.

Chronos

The DBS-MS 500 HCT is controlled by Chronos. Chronos additionally transfers information such as sample and barcode data directly into the MS software and triggers the analytical method.

Optimization for high throughput

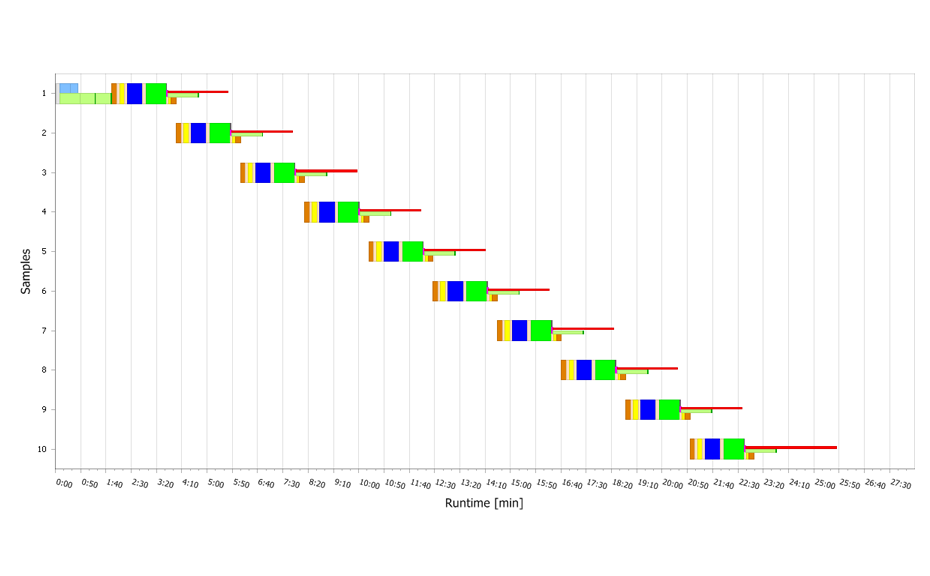

Chronos’ core feature is to allow an overlap of workflows. The software measures the time for each work step in real-time and adapts the sample schedule accordingly, even while an analysis is still ongoing. This enables the DBS-MS 500 HCT to prepare the next sample in time and therefore avoids delays due to idle time. As a result, Chronos increases the active measuring time of the devices and considerably raises the efficiency of the laboratory.

Real-time analysis monitoring

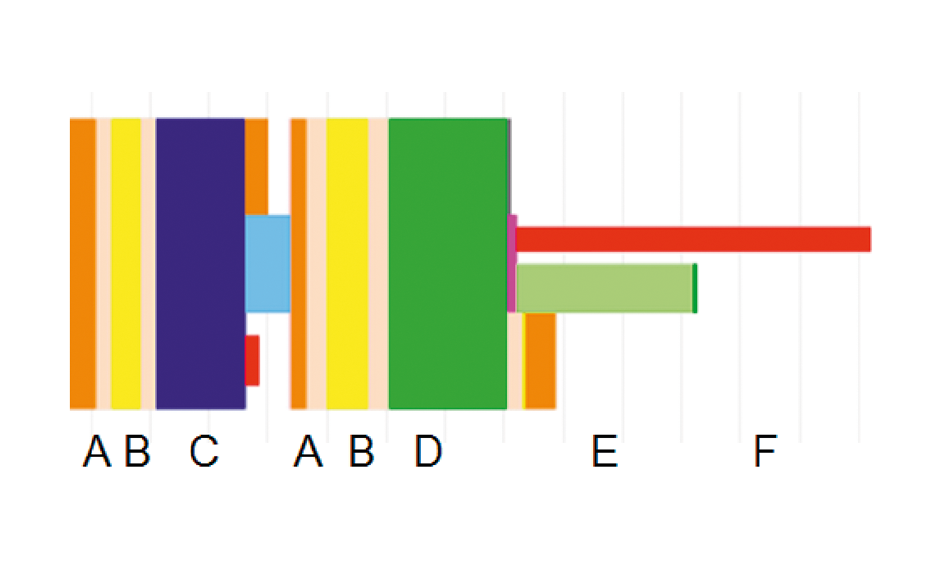

The sample schedule is visualized in a chart which can be monitored in real-time (see image slider below).

A) Transport the DBS card

B) Optical card recognition

C) Application of internal standard

D) Extraction

E) Rinsing the extraction unit

F) Estimated LC-MS cycle time

Robustness and repeatability

The user can create methods with almost no limitations on parameter options. Sample lists can be quickly generated and adapted to individual needs for the standard user. Robustness and reproducibility are thus ensured through software-controlled automation of the complete analysis.

Safety

Chronos not only controls your analytical system, but also reports a 2D barcode, the run parameters of your analytical system, and pictures of each DBS card. The 2D barcode automatically assigned to each DBS simplifies handling and avoids errors that might be caused by manual working steps. Chronos ensures traceability of every sample, thus supporting a good documentation practice.

Downloads

Technical Specifications

Height

660 mm

Width

1260 mm

Depth

800 mm

Weight

130 kg

Mains voltage

115 / 230 V AC

Frequency

50 / 60 Hz

Power consumption

Max. 130 W

Main fuse

2 AT

Nitrogen connection

5.5 – 8 bar

Ingress protection (IP)

IP20

In-output connections

2 x RJ45

Power supply

Gas supply

Service connector

Ordering Information

050.0501

CAMAG® DBS-MS 500 HCT

- Fully automated DBS workstation for 500 DBS cards.

- Including wash station, optical card recognition unit, hematocrit scanner, and internal standard spraying module.

- Master slave control unit.

- Chronos software to control the extraction, analysis, and PAL sample collection.